- #Profibus testing software generator

- #Profibus testing software download

- #Profibus testing software free

Use of PROFINET in safety-related system components by use of PROFIsafe user profile.ĭuring the development of your PROFINET field device, you have access to the following tools free of charge:GSD-Editor zum Erstellen von GSD-Dateien für PNO Mitglieder im Downloadbereich bei Guaranteed interoperability through certified products in all automation systems.Īutomatic data updates on voltage recovery by employing the Universal Parameter Server. When a node fails, the other nodes remain unaffected by this failure.Įxtensive training concept available worldwide. Offered by a large number of different companies.Ĭomprehensive service and training offered by Competence Centers of PROFIBUS & PROFINET International (PI) around the world. The transition from PROFIBUS DP and PROFIBUS PA is seamlessly implemented. PROFIBUS is available in the form of PROFIBUS DP for the manufacturing industry and as PROFIBUS PA for the process industry. Isochronous data transmission for high-performance applications. High-speed data transmission up to 12 Mbps.Ĭomplete execution of communication in the hardware. Certified field devices have been available in the form of PROFIBUS DP since 1994.Įasy to implement with PROFIBUS ASICs from various manufacturers currently available on the market. PROFIBUS is currently the market leader for fieldbus communication with approximately 40 million installed nodes.

#Profibus testing software generator

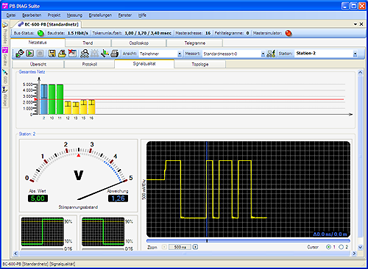

The load test generator (Security Level 1) is available free of charge to PNO members in the Downloads area of the PNO homepage PROFIBUS Highlights

#Profibus testing software download

The corresponding schemes are also available for download on the PNO website.

The GSDML Viewer for viewing and verifying GSD files is available free of charge to PNO members in the Downloads area on the PNO homepage files can be created with any standard XML editor.

PROFINET guarantees a high standard of quality for industrial communication PROFINET offers added value for manufacturers and end users thanks to the integration into field devices, because: Modular development kits adapted to match your development projects.ĭevelopment kits guarantee a quick introduction to development topics and offer a complete development environment.ĬomDeC supports you at any stage of field device development.Ĭomprehensive training concept available. Hardware support based on ERTEC is additionally available for synchronized communication. PROFINET can be implemented with currently available standard Ethernet controllers without any changes in the hardware. Quicker system startup using Fast Startup The use of IT technologies has created new possibilities for automation: For example, access via standard browser to the web server of a field device or wireless communication in an industrial environment. Standard Ethernet technology guarantees flexible network topologies with line, ring and star topologies as well as wireless and fiber optic solutions. The functional scope ranges from the non-synchronized Ethernet-based communication (PROFINET with real-time functionality), all the way to extremely high-speed I/O signal transmission and demanding synchronized communication for motion control applications: PROFINET with isochronous IRT communication. Its modular design enables simple control tasks all the way to complex, time-critical applications (e.g. PROFINET can be implemented with any available standard Ethernet controller, since it is fully based on IEEE 802.xx Switched Ethernet technology with full-duplex and 100 Mbps.

0 kommentar(er)

0 kommentar(er)